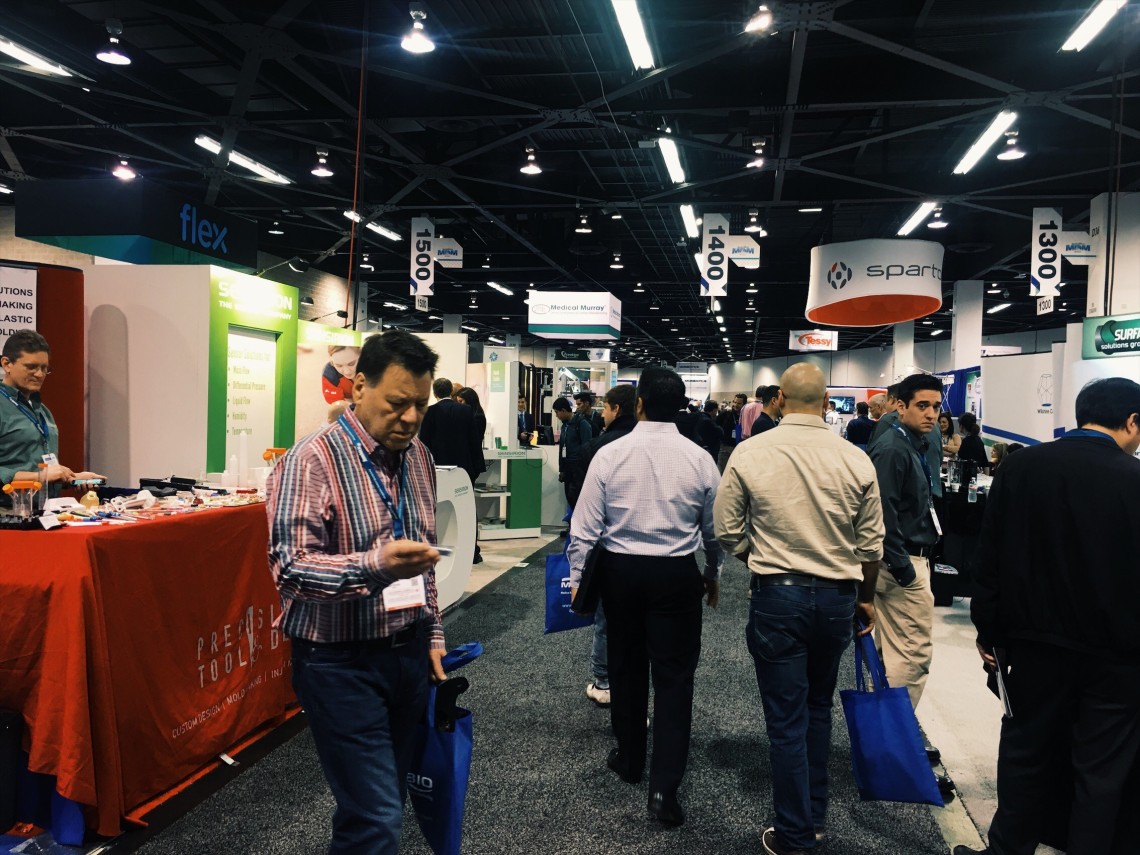

On Wednesday, the IBS Electronics Team checked-into Day 2 of the MD&M West Exposition, hosted at the Anaheim Convention Center in California. MD&M West is a 3-Day exposition of the largest, most advanced design and manufacturing technology in the world.

This event annually draws thousands of original equipment manufacturers (OEMs), contract and design manufacturers (CDM), and distributors such as IBS Electronics. MD&M West is also valuable for those interested in robotics manufacturing, from prototyping, upgrading automated equipment, to choosing a compatible packaging solution.

Smart Manufacturing

There is no doubt that the world of manufacturing is changing. Every year introduces an improved, redesigned, and more than likely—automated—way of manufacturing components and medical equipment. This year, MD&M West interestingly focused on “the Rise of the Cobots,” or collaborative robots.

Rise of the Cobot

So, what is a cobot? Cobots are essentially robots, typically robotic arms, that are designed to interact with humans in a communal work space. Cobots are a departure from tradition robots, which are fully autonomous and require very limited instruction. In recent years, the market has seen a skyrocketing increase in robotics investment ventures.

The driving factor behind the cobots’ appeal in recent years, is they carry a wide array of useful applications. From gluing, mounting, picking up, placing, packaging, polishing, and more, cobots are consolidating manufacturing processes—and more people are noticing. Some companies even adopt cobots for ergonomic purposes, as they ease muscular and skeletal strain on their employees.

When the IBS Team observed the latest robotic, CNC, and automated technology in action, the swift rise of the cobot was a no-brainer. For one, robots are extremely cost-effective with a large ROI. Additionally, cobots streamline and optimize processes in nearly any medical product operation and beyond (plus, they look seriously cool). With this year’s MD&M West focus on “smart” manufacturing, the IBS Electronics team was convinced that the future is hi-tech.

From Concept to Market

MD&M West is broken up into five major sections, each with a different focus. Whether attendees are interested in sourcing adequate raw materials, finding the right components, testing solutions, sensors, or packaging solution, there’s a niche for every application. For those investing in new product ventures or designs, MD&M West is a great place to get a little inspiration.

IBS Electronics, One Step Ahead

As a global electronic component distributor and provider of innovative logistic solutions, IBS Electronics actively engages in the latest design and smart manufacturing processes. Our knowledgeable team proactively updates its knowledge database to better assist our clients. In order to be competitive in today’s market, you should be well-versed in the latest technology. At IBS Electronics, we prefer to stay one step ahead.

Why We Are One

For over 40 years, IBS Electronics Group has provided a broad range of integrated supply chain and electronicsmanufacturing solutions tailored specific to our customer's operations. As your one source for the industry’s top brands all in one place, our engineers specialize in reducing supply chain complexity and are here to provide you with dedicated support from prototype to production.

.png)

.png?resizemode=force&maxsidesize=96)