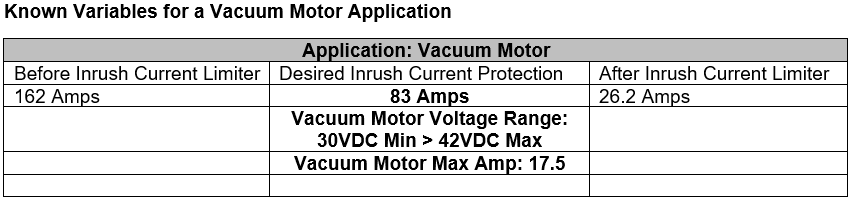

nrush current can cause considerable damage to electrical applications, making it essential to control the starting current with the right inrush current limiter. In this article, we will explore the potential consequences of selecting an inappropriate circuit protection device, as well as how Ametherm can help you choose the right one. To illustrate the dramatic difference between using an inrush resistor and not using one, we will use a vacuum motor as an example.

A Vacuum Motor Application

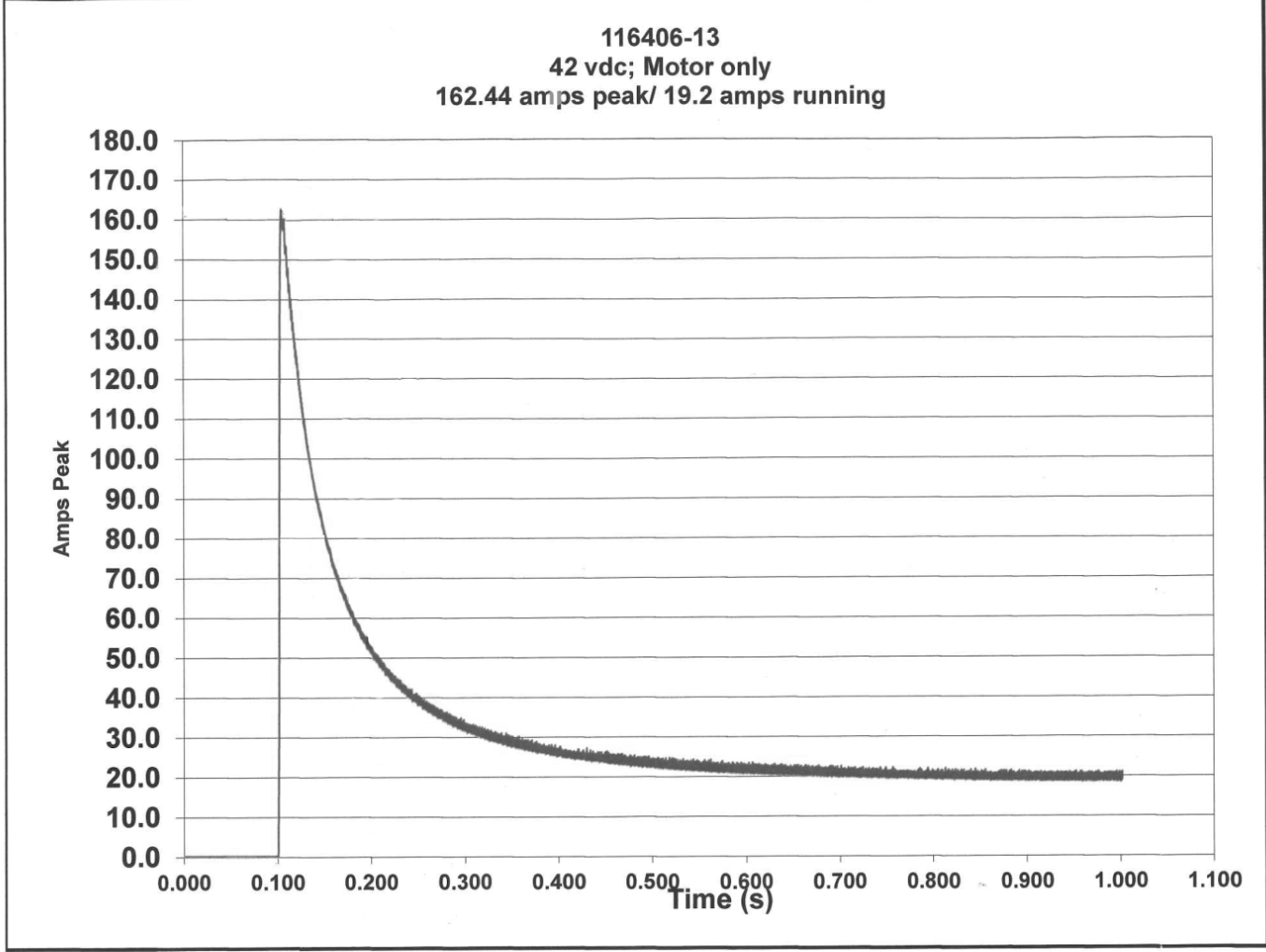

We started with a customer who had a vacuum motor with known variables. Before seeking assistance from Ametherm, the customer had already selected an MS32 10015 inrush current limiter, which was rated for 15 amps of steady state current. Despite this, the customer ran the vacuum motor with additional series resistance for over 5 minutes at 17 amps of steady state current, resulting in the inrush resistor failing.

Choosing the Right Inrush Current Limiter

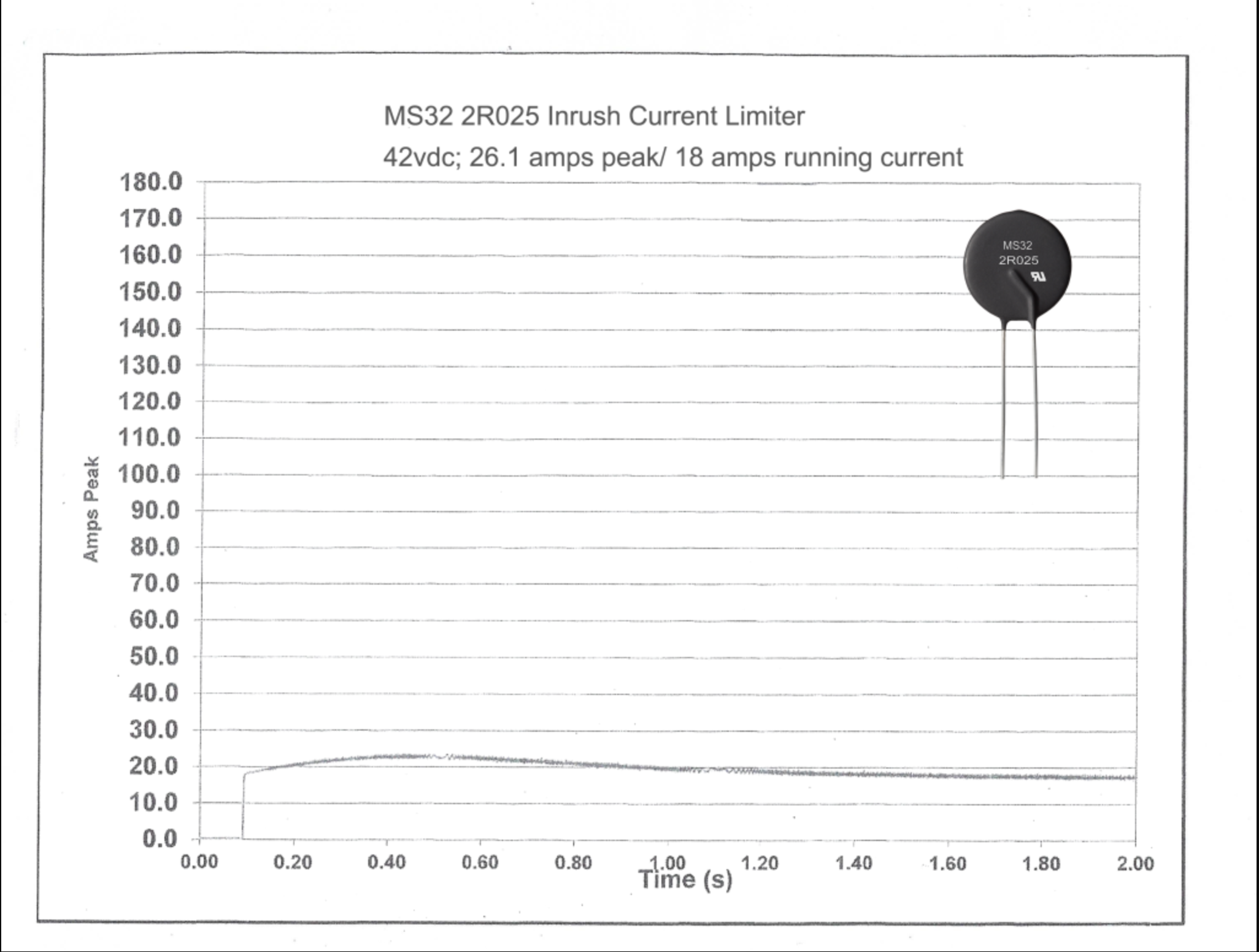

The customer approached Ametherm for assistance, and the engineers conducted a thorough review of the problem. They recommended using an MS32 2R025 power thermistor, rated at 25 amps of steady-state current. When the vacuum motor ran for more than five minutes, the inrush protection device displayed 26.1 amps at peak and 18 amps of steady-state current [see Illustration 1]. Although the MS32 2R025 inrush resistor performed adequately, the body temperature of 213 ºC was higher than the customer desired.To reduce the body temperature of the MS32 2R025 power thermistor, the engineering team next suggested using an SL32 1R030 inrush protection device [See illustration 2]. This inrush resistor ran for over 5 minutes at 23.3 amps at peak and 18 amps steady state current. By using the SL32 1R030, the body temperature dropped 30 ºC, to 182 ºC.

Illustration 1 MS32 2R025 Inrush Current Limiter (Ametherm, 2019)

Illustration 1 MS32 2R025 Inrush Current Limiter (Ametherm, 2019)

To reduce the body temperature of the MS32 2R025 power thermistor, the engineering team next suggested using an SL32 1R030 inrush protection device [See illustration 2]. This inrush resistor ran for over 5 minutes at 23.3 amps at peak and 18 amps steady state current. By using the SL32 1R030, the body temperature dropped 30 ºC, to 182 ºC.

Illustration 2 SL32 1R030 Inrush Current Limiter (Ametherm, 2019)

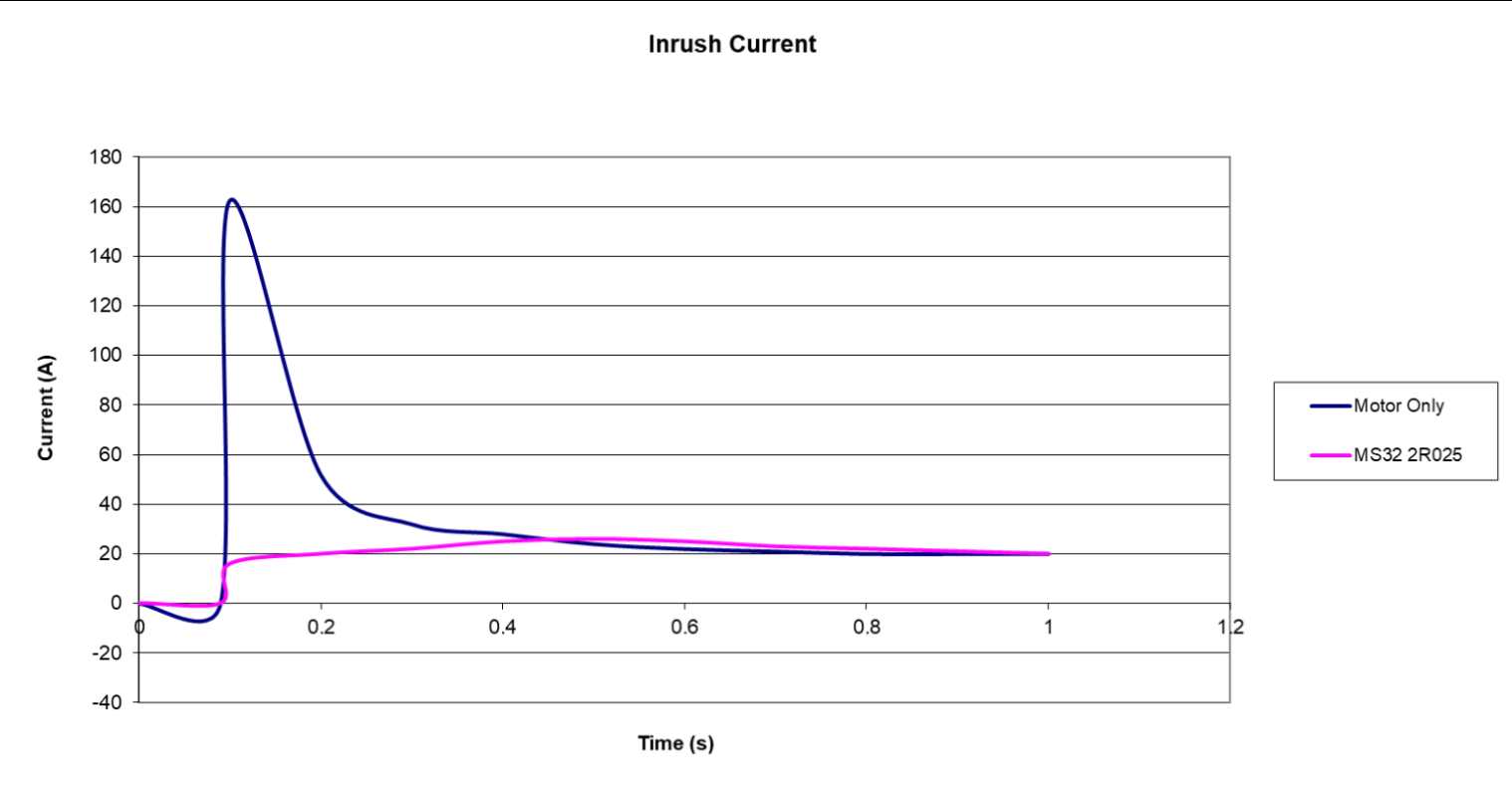

Both the MS32 2R025 and the SL32 1R030 current flow limiters controlled the high inrush current by reducing it from 162 amps to 19 amps [See illustrations 3 and 4].

Inrush Current Limiter Effectiveness

From this test we can see how effective circuit protection devices are. The power thermistors reduced the initial current of the vacuum motor by more than 80%. The same conclusions can be applied to many other applications, such as transformers, power supplies, green energy, energy storage, and more. This proves that it is cost-effective to use an inrush protection device where a different design might be more expensive.

Inrush current limiters can significantly improve the efficiency and performance of vacuum motors experiencing high inrush current. If you have any questions about Ametherm’s inrush current limiters or need engineering solutions, the experts at IBS Electronics are ready to provide you with the answers and solutions you need.

(This Article content originally appeared on Ametherm Blog)

Why We Are One

For over 40 years, IBS Electronics Group has provided a broad range of integrated supply chain and electronicsmanufacturing solutions tailored specific to our customer's operations. As your one source for the industry’s top brands all in one place, our engineers specialize in reducing supply chain complexity and are here to provide you with dedicated support from prototype to production.

.png)

.png?resizemode=force&maxsidesize=96)